MartenWear heat treatment for ultra-long wear debris resistant surfaces

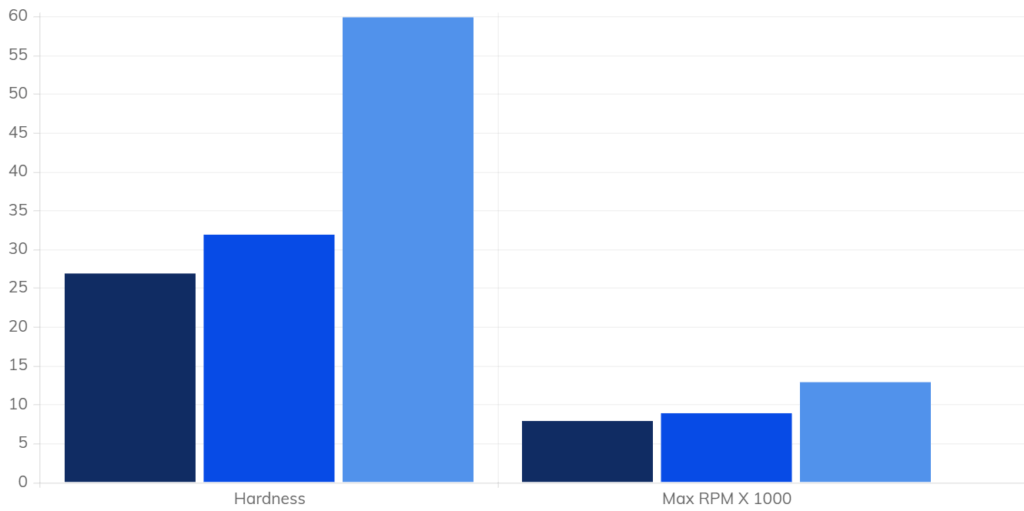

Our MartenWear process developed and applied all in house is a 2nd stage of heat treatment to our billet components. MartenWear heat treats the exterior surface of the part to be extremely hard and long wearing. This surface is more robust against debris ingestion and has been found to be wear free in all applications up to and beyond 13000 RPM. This process is available for most of our steel billet components.

Specification:

- Vickers; 620 – 720

- Rockwell C: 55 – 60

- Maximum Tested RPM: 13,000

- RPM Limit: Unknown